What Is a Fully Automatic Die-Cutting Machine?

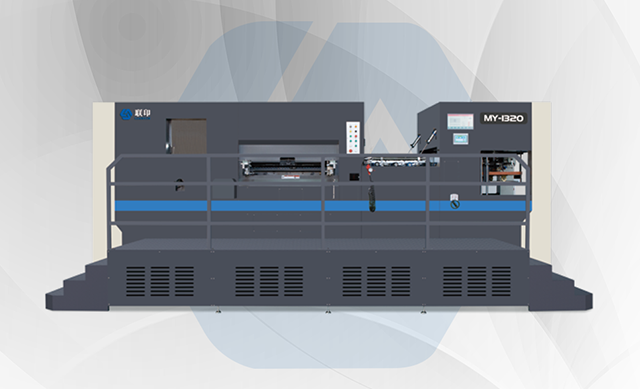

A fully automatic die-cutting machine is a high-precision industrial device designed to cut, emboss, and shape materials with minimal human intervention. Unlike manual or semi-automatic machines, it provides high-speed, consistent, and repeatable performance, making it essential for modern manufacturing industries.

These machines are widely used in packaging, printing, textiles, electronics, and promotional product manufacturing. By automating the die-cutting process, manufacturers can increase productivity, reduce labor costs, and improve product quality. Typical applications include custom boxes, labels, greeting cards, decorative patterns, and luxury packaging.

Fully automatic die-cutting machines offer multiple benefits that make them indispensable in large-scale production environments:

Automated feeding and die alignment reduce downtime

Capable of continuous operation for extended production runs

Increases output compared to semi-automatic machines by 50–80%

Accurate cutting and embossing with minimal errors

Repeatable results across large batch production

Ensures high-quality finishes for luxury and complex products

Compatible with various materials: paper, cardboard, plastics, foil, and fabric

Supports multiple processes: cutting, embossing, foil stamping, and scoring

Suitable for custom and complex shapes

Minimal operator intervention required

Reduces human errors

Frees skilled labor for other production tasks

Lower material waste due to precise cutting

Reduced labor costs and rework

Long-term return on investment due to durability and productivity

These advantages make fully automatic die-cutting machines an essential investment for manufacturers aiming to optimize production efficiency and product quality.

Proper maintenance is critical to ensure optimal performance and longevity of fully automatic die-cutting machines. Regular upkeep minimizes downtime and reduces the likelihood of costly repairs.

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Clean feed rollers, lubricate moving parts, check for paper jams |

| Weekly | Inspect dies and rollers for wear, check pneumatic and hydraulic components, clean dust accumulation |

| Monthly | Calibrate sensors, check pressure and temperature settings, inspect bearings |

| Quarterly | Deep cleaning, software updates, check electrical connections and safety systems |

| Annually | Complete mechanical and electrical inspection, replace worn-out components, test overall machine accuracy |

Use manufacturer-recommended lubricants for moving parts

Keep feeding and delivery areas free of dust and debris

Inspect cutting dies and foil stamping components for wear

Document maintenance logs to track machine performance over time

Even with proper care, operators may encounter minor issues during operation. Understanding common problems and solutions ensures smooth production.

Cause: Improper material alignment or suction failure

Solution: Adjust feed rollers and vacuum pressure; realign material stack

Cause: Incorrect die pressure, temperature, or worn dies

Solution: Calibrate pressure, adjust heating units, and replace worn dies

Cause: Overuse or mechanical resistance in feed mechanisms

Solution: Check servo motor settings, clean and lubricate bearings, ensure no obstructions

Cause: Tension misalignment or incorrect feed speed

Solution: Adjust foil tension rollers and speed settings

Cause: Loose connections or software issues

Solution: Inspect wiring, reset the control system, update software as needed

Proactive troubleshooting, combined with regular maintenance, ensures long-term reliability and consistent performance.

Proper installation and setup are vital for safe and efficient operation:

Ensure sufficient floor space for the machine and operator access

Provide stable power supply and grounding

Maintain adequate lighting and ventilation

Place the machine on a leveled surface

Connect electrical, pneumatic, and hydraulic systems

Align feed and delivery units

Install cutting dies and heating elements

Conduct pre-operational testing before production

Operators must wear protective gloves and eyewear

Emergency stop buttons should be tested regularly

Keep hands and tools away from moving parts

Following proper installation and safety protocols reduces accidents and ensures optimal machine performance.

Fully automatic die-cutting machines are versatile and widely used across multiple sectors:

Luxury gift boxes, cosmetic packaging, wine boxes

Precision inserts and custom designs

Reduces material waste while maintaining high-quality finishes

Greeting cards, labels, book covers, promotional materials

Supports complex embossing and foil stamping

Enhances visual appeal and brand identity

Cutting fabric patterns, plastics, and composite materials

Produces intricate shapes for components

Suitable for batch and mass production

Their versatility allows manufacturers to meet diverse market demands while maintaining speed, precision, and quality.

A fully automatic die-cutting machine is an indispensable tool for modern manufacturing, offering precision, efficiency, and versatility. By implementing a structured maintenance schedule, proactively addressing common issues, and adhering to installation and operational guidelines, manufacturers can maximize productivity and extend machine lifespan.

These machines are highly beneficial for packaging, printing, textiles, and electronics industries, providing high-quality output and cost-effective production. Investing in a fully automatic die-cutting machine ensures that companies remain competitive, efficient, and capable of delivering premium products to their customers.

Este site usa cookies para garantir que você tenha a melhor experiência em nosso site.

Comente

(0)